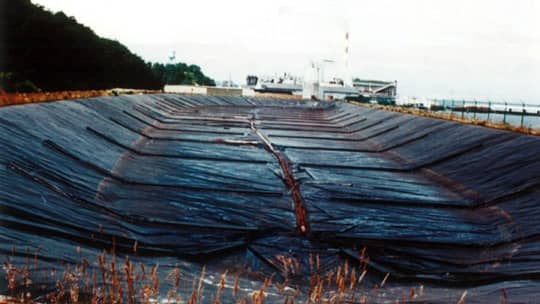

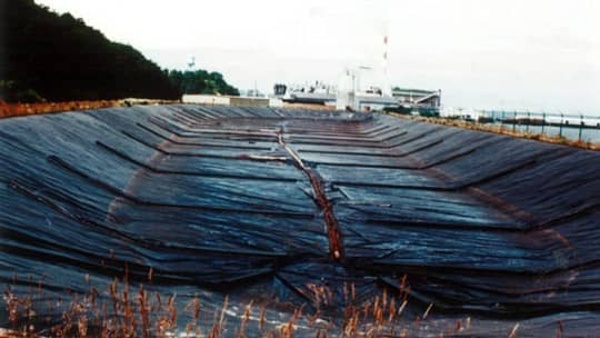

Floating covers manufactured from geomembranes are a popular solution to odor containment and an integral component of low-rate anaerobic digestion systems. Seaman Corporation's XR-5® Geomembranes offer many features that are unmatched for this application. XR-5 Geomembranes provide superior seam strength under constant loading and temperature fluctuations and are essential to personnel who walk on floating covers.

A Floating Cover Liner You Can Trust

XR-5 Geomembranes significantly reduce the number of field seams. Additionally, their low thermal expansion and contraction properties make operation and maintenance simple. The broad range of chemical resistance and flexible nature of the membrane make it the ideal material for floating cover construction.

Floating Cover Applications

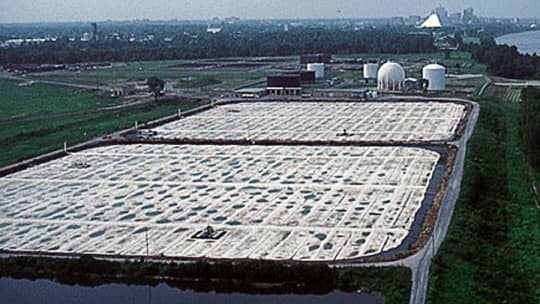

In floating cover applications, reinforced geomembranes are laid on the surface of a pond. A buoyancy system is created by ethyl foam tubes wrapped by the geomembrane, allowing the cover to stay afloat. Due to these ethyl foam tubes, the reinforced geomembrane liner has the ability to rise and fall in accordance with the level of contained liquid. Some floating cover applications include:

- Methane collection for anaerobic digesters

- Preventing algae growth

- Preventing contaminants from entering the pond

- Preventing chemicals from being exposed to the air odor control

- Animal control

Pond, Reservoir, and Geomembrane Lagoon Covers

When a pond, lagoon, or reservoir is lined, the goal is to achieve an impermeable containment system. This liner system will prevent hazardous liquid from contaminating and coming in contact with the soil’s water table. If the water table were to become contaminated, it would potentially bring harm to the wildlife and people who drink the surrounding groundwater.