Geomembranes that come from the factory, either as sheet materials or as panels from a second manufacturing process, rarely leak. Leaks occur primarily from three areas:

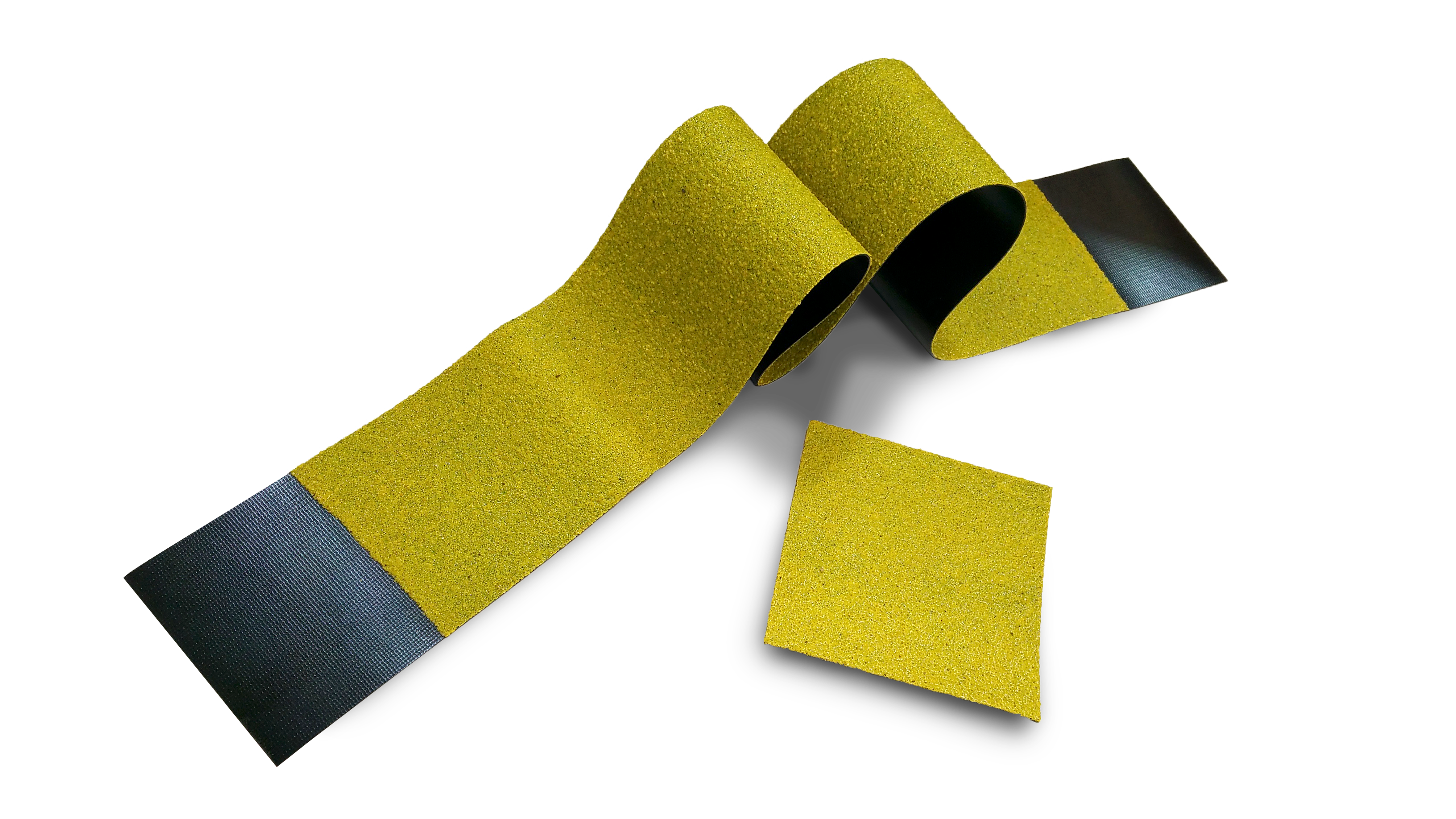

Geomembranes usually require attachments and other terminations that must be sealed properly. Also, there are areas that typically require special attention to ensure leakproof work. In these situations, there are accessories that help the installer complete the geomembrane barrier. In this blog, we will review the accessories that are offered with the XR-5® Ethylene Copolymer Geomembrane. There are six principal items that are available to support the completion of the XR-5 Geomembrane installation.

Series: Geomembrane Selection & Design for Elevated Temperature Containment

Post 2: Top 4 Factors to Consider When Specifying and Designing Geomembrane Systems for High-Temperature Applications

Series: Geomembrane Selection & Design for Elevated Temperature Containment

Post 1: Geomembrane Installations Prone to Elevated Temperature Exposure

[Wooster, Ohio] – [2/26/25] – XR® Geomembranes is proud to announce the celebration of its 50th anniversary, marking five decades of providing innovative geomembrane solutions to industries worldwide.

The term “weathering” on first glance appears to be straightforward. Most in the geomembrane industry consider it to narrowly describe sunlight or UV resistance only. In fact, testing and property specifications are often only from a sunlight exposure standpoint. But the effects of changing temperatures, precipitation, wind, etc. can be factors of destruction for geomembranes.

Series: Efficient Reclaimed Water Storage Using Geomembranes

Part 2: 4 Key Factors in Selecting Reinforced Ethylene CoPolymer Geomembranes for Reuse Impoundment Applications

Series: Efficient Reclaimed Water Storage Using Geomembranes

Part 1: Water Reuse in the U.S.: Top Opportunities and Challenges

For several years, the U.S. Congress has considered legislation encouraging the use of innovative construction materials. A specific bill termed “Innovative Materials in American Growth and Infrastructure Newly Expanded” or called “IMAGINE,” was first introduced in 2018. It was again introduced in 2021 as a result of the increased infrastructure expenditures anticipated for the Infrastructure Investment and Jobs Act (IIJA), also in 2021. While the bill has not been previously approved and enacted, it was reintroduced in November 2023. As a summary, IMAGINE has these principal goals: