Dr. Robert Koerner, professor emeritus of civil engineering at Drexel University, is a highly respected professional in both the geosynthetic and engineering communities. In his webinar, “Wave (or Wrinkle),” Koerner covers unreinforced geomembranes, such as HDPE, and how geomembrane waves or wrinkles can be somewhat prevented and/or fixed. Here is an overview of the webinar:

Dr. Robert Koerner, professor emeritus of civil engineering at Drexel University, is a highly respected professional in both the geosynthetic and engineering communities. In his webinar, “Wave (or Wrinkle),” Koerner covers unreinforced geomembranes, such as HDPE, and how geomembrane waves or wrinkles can be somewhat prevented and/or fixed. Here is an overview of the webinar:

Why Waves Occur in Unreinforced Geomembranes

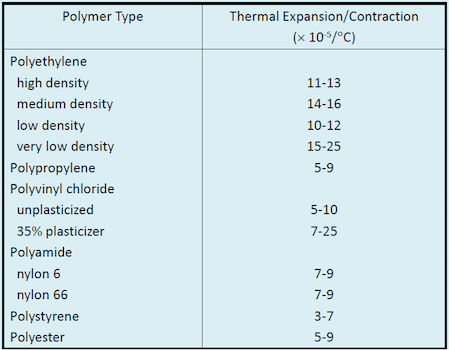

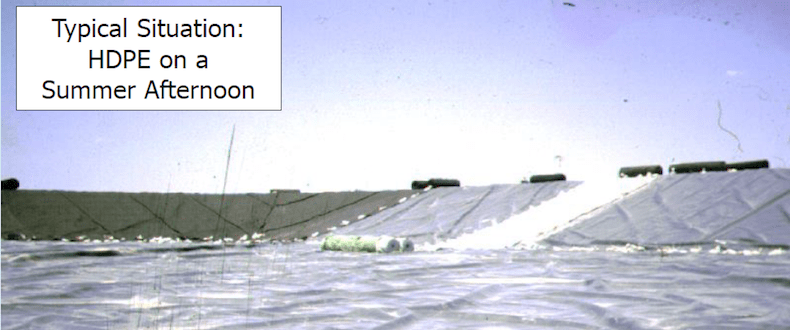

Waves are created by temperature-induced thermal expansion/contraction properties in a geomembrane liner, and every geomembrane liner has a different thermal expansion/contraction coefficient as listed in the table below. The higher the coefficient, the higher the expansion/contraction capabilities and the larger the waves. The table also shows how and why polyethylene (HDPE) is well known for its expansion/contraction properties.

According to Koerner, waves and wrinkles can be problematic because they:

- Violate both federal and state regulations

- Create mini-dams

- Cause geomembranes to fold, which leads to cracking

- Increase the chance unreinforcedgeomembranes can be damaged by backfill machinery

- Decrease the life cycle of membranes by creating stress in concentrated areas

- Cause a loss in HDPE geomembrane liner integrity (tensile strain and distortion)

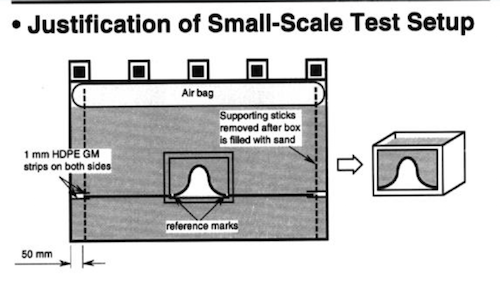

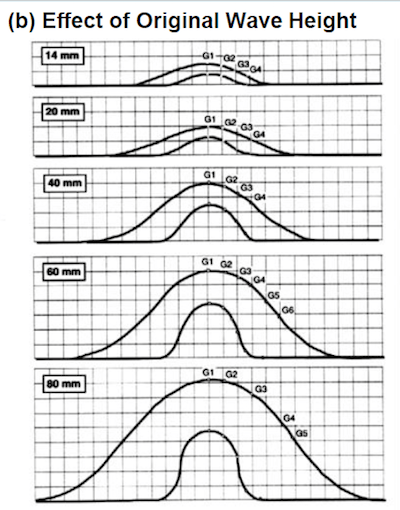

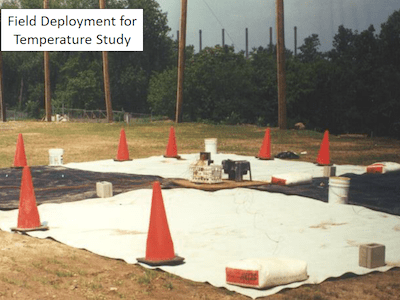

During his years of research on the topic, Koerner, along with T.Y. Soong, another geosynthetic expert, found that thinner, unreinforced geomembranes tend to have many small waves, while thicker and stiffer unreinforced geomembranes tend to have a few large waves. Together, they created two different test methods that were designed specifically to analyze geomembrane waves.

Koerner and Soong concluded that waves never go away after they have already formed, no matter how much soil or pressure is placed on top of a geomembrane liner. It turns out waves create an airtight void that cannot be dissipated or pushed out regardless of the pressure/weight added (this is depicted in the two diagrams below).

Time-Consuming Solutions

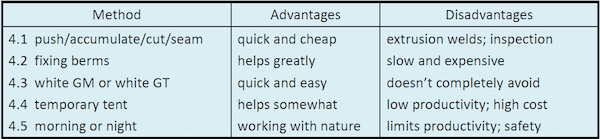

While placing weight on top of a membrane may not fix a wave or wrinkle, there are actually many cheap but time-consuming ways waves and wrinkles can be fixed, as explained in the below table and bullet points taken from Koerner’s webinar.

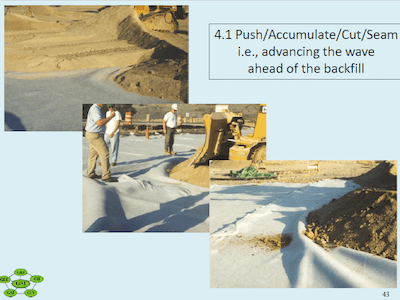

Push/Accumulate/Cut/Seam Method:

This method takes the installed waves and pushes them out with weight from soil and heavy machinery. The geomembrane wave is then cut, overlapped, and welded together to create a smooth surface.

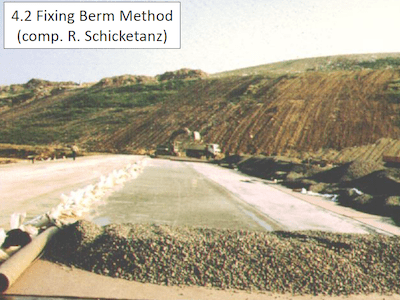

Fixing Berms Method:

The HDPE geomembrane liner is laid down during the hottest point in the day and is pulled tight (still with wrinkles) and pinned down around the perimeter with soil. The liner then sits overnight and contracts due to ambient cold temperatures that pull it tight to provide a smooth surface (thanks to its thermal contraction capabilities). The liner is then covered with soil in the early morning hours before the ambient warm temperatures expand and create wrinkles in the liner.

White GM (Unreinforced Geomembrane) or White GT (Geotextile) Covering a Black GM Method:

The white geomembrane surfaces collect less heat and therefore don’t expand to the degree non-white material does. Note that this method still doesn’t completely prevent waves.

Temporary Tent Method:

This method covers the whole geomembrane installation to prevent the sun’s heat from expanding the geomembrane and creating wrinkles.

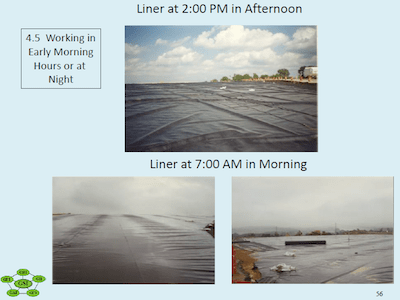

Morning or Night Method:

This method calls for installing the geomembrane during the low-temperature times of the day to prevent wrinkles. This provides only a small window of opportunity and can be unsafe because the coldest parts of a day usually have low levels of sunlight.

4.1 Push/Acculumate/Cut/Seam Method

4.1 Push/Acculumate/Cut/Seam Method

4.3 White GM or White GT Method

One of the more interesting solutions, mentioned above, is the use of a white geotextile or white geomembrane to cover a dark geomembrane. The white surfaces accumulate less heat and lower temperatures to reduce the number of geomembrane waves or wrinkles, but not getting rid of them completely.

Important Webinar Takeaways

- The addition of pressure/weight does not fix unreinforced geomembrane waves or wrinkles.

- Waves and wrinkles can collapse and form creases that lead to cracking.

- Waves and wrinkles decrease a geomembrane’s life cycle.

- Unreinforced geomembrane installation must be done quickly if a liner is made of a material that is prone to thermal expansion/contraction, and quick installation takes a lot of attention and planning.

- Fixing an unreinforced geomembrane wave or wrinkle can become time-consuming and expensive.

Attendees of Koerner’s webinar noticed every test was done with an unreinforced HDPE geomembrane liner, leading them to ask why a reinforced geomembrane liner wasn’t included in the study. Koerner acknowledged that some attendees believed reinforced geomembranes could provide different results and concluded that he would consider doing the same test on reinforced geomembranes in the future.

For another perspective, check out Glen Toepfer’s blog on the same webinar. Also, compare membrane strength, ease of installation, and more in our blog, “XR® Geomembranes vs. HDPE.”