Many engineers would argue that geomembranes are only fluid barriers and are not meant to be load bearing in any manner. All loads should be carried by geosynthetic counterparts, such as geotextiles, geogrids, etc., that are placed over and under the geomembrane. However, from a materials and installation standpoint, it is virtually impossible to transmit all load to the adjacent layers. Additionally, it is not usually cost-effective to build a heavily redundant composite system that takes all mechanical bearing off the geomembrane.

XR-5 Geomembrane Installation, Flow Equalization Basin, Batesville, Indiana

XR-5 Geomembrane Installation, Flow Equalization Basin, Batesville, Indiana

Geomembranes, like most engineered materials, are subjected to loads and will fail under certain conditions. In a broad sense, you could assume mechanical failure would be defined as a failure to carry a subjected load. And it would not be failure from an environmental influence, such as UV, thermal stresses, or chemical attack—although all could weaken the membrane, and/or concentrate loading, resulting in a mechanical failure.

Four Types of Loading That Can Lead to Failure

Consider these four major mechanical stresses that can cause geomembrane failure and how to prevent them:

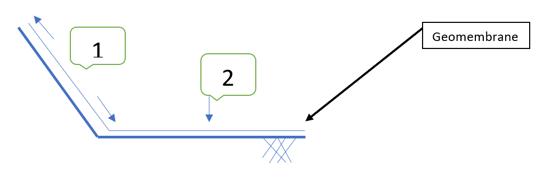

- Slope loading. Includes the weight of the geomembrane itself and any cover or additional geosynthetic layers; the geomembrane is on a slope or installed vertically, carrying the weight down slope.

In the case of an uncovered noncrystalline liner, loading is the weight of the liner alone minus friction. For an uncovered crystalline geomembrane, such as high-density polyethylene, there are thermally induced stresses added.

If covered, additional load is added from the overburden and redundant load-bearing layers seek to take some load off the geomembrane. If the load parallel to the membrane exceeds yield tensile strength, failure occurs. Use a high-yield-strength geomembrane and eliminate overburden if possible. - Puncture from above or below. Puncture can be caused by uneven subgrade or sharp objects under, or over, the liner. Failure is from normal loads and can be localized or widespread. Puncture failure comparisons of unreinforced films vs. heavily reinforced geomembranes have been shown to have widely different localized puncture resistance. High-puncture-strength products provide greater assurance. Read more here.

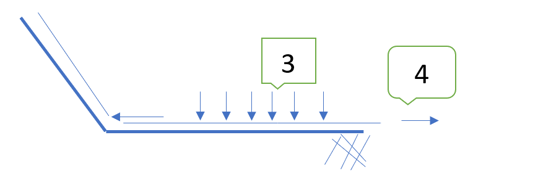

- Uniform Loading, solid or liquid. Voids under the liner can cause the material to bridge and induce a larger puncture. If it stretches, thickness reduces and in the case of films, where puncture strength is directly proportional to thickness, localized punctures can occur. Reinforced geomembranes are more likely to carry load and maintain other mechanical properties.

- Tensile load induced by normal load from above. The forces in No. 3 above additionally transmit load in a horizontal direction so failure can occur as a tensile failure at yield. High modulus geomembranes, such as the heavily reinforced XR-5 products, carry more load to failure than films and laminated materials.

Three Strategies to Avoid Failure

To avoid the stresses listed above, here are three strategies to consider when specifying a geomembrane system:

1. Evaluate using one with low thermal expansion and contraction characteristics whereby it can be used without overburden.

2. Check anticipated slope loads, design accordingly.

3. Consider alternate ways to ensure a smooth, stable subgrade, such as adding smooth base materials and or using geotextiles.

Constructability should deal with these basic mechanical failure mechanisms, incorporating product selection and application in the design process.