What laboratory properties are critical in the selection criteria for geomembranes?

Part 2: Defining the critical geomembrane survivability properties

In Part 1 of this series on essential geomembrane properties, two broad categories were defined each with 3 essential supporting properties:

Chemical/Environmental Resistance

1. UV

2. Chemical Resistance

3. Thermal Stability

Survivability

4. Tensile/Yield Strength

5. Seam Strength/Dead Load Seam Strength

6. Puncture

Part 1 defined the Chemical/Environmental resistance properties along with discussion on the ability to relate these properties to field conditions. In this second part, we will cover the three properties which allow a designer to take lab data and relate it to field conditions to ensure Geomembrane Survivability, both the rigors of installation and maintaining long term physical strength.

Survivability

4. Tensile/Yield Strength – Tensile loading is introduced onto a geomembrane in many ways. Often normal loading is transmitted as tensile. Adjacent backfill creates skin friction which is tensile. Dragging and placing geomembrane sheet panels places direct in-plane tensile loading on the material. Typically, one of the first properties a manufacturer will list on a specification sheet, tensile properties are often listed just simply as that, tensile. In fact, knowing more detail on tensile is particularly important when predicting the survivability of a geomembrane. What is the yield vs. break tensile? What is the tensile strength under elevated temperature? ASTM has test methods for both Grab and Strip Tensile. Grab is a more realistic measure as it measures tensile strength of a larger specimen, more indicative of field conditions. Grab tensile is a good indicator of field performance.

Tensioned XR-5 Ethylene CoPolymer Geomembrane Exposed Landfill cover

New York, USA

5. Seam Strength/Dead Load Seam Strength – Geomembrane seams are necessary to complete an installation. Some stiff products are laid in a “board” like fashion with many field seams, whereas flexible polymer products are factory manufactured into larger sheets. If seams are weaker than the parent material, the discussion regarding tensile of the geomembrane sheet is irrelevant and the seam strength is the weaker link. For this reason, many geomembrane manufacturers do not publish minimum seam strength specifications. Laboratory measures of seam strength provide meaningful design information on the true integrity of the geomembrane from a tensile loading standpoint. It is uncommon to install a geomembrane system without some seams being loaded in shear; i.e., loaded perpendicular to the seam, in-plane.

Geomembranes are often under constant tensile loading, including the seams. That loading is measured as Dead Load Seam Strength. A quite common example is geomembranes on a slope, either uncovered and subject to UV, or covered with redundant geosynthetic layers and/or overburden. While some products recommend that no seams be perpendicular to the slope, it is usually inevitable that some will be. Laboratory dead load measures the sustained load which a geomembrane can carry in tensile (shear), without stretching or failure. Both stretch and breakage will result in the lack of tensile strength and may represent a field failure, depending on the function and design. This is a test that is measured at both ambient and elevated temperatures. It is an essential component of survivability, and the ASTM Dead Load Test is a good measure of field performance.

Fuel Storage Secondary Containment

Liege, Belgium

Sanitary Sewer Overflow Impoundments

Mobile, Alabama USA

XR-5 Ethylene Copolymer Geomembrane lined applications under tension

on exposed steep slopes.

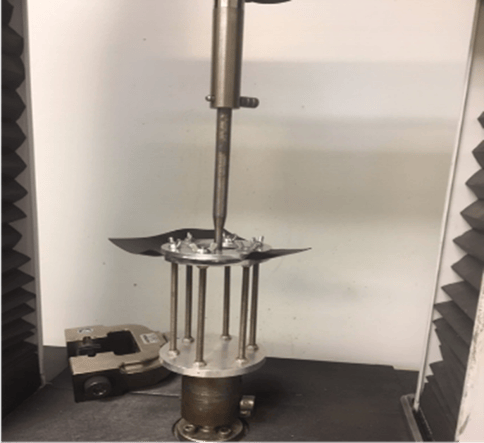

6. Puncture Resistance – Laboratory puncture resistance tests vary by the type and size of the puncturing tip. Some attempt to simulate a sharp protrusion, while others a more rounded protrusion. These are index properties and a direct correlation to field environments is difficult. Regardless, puncture testing can provide valuable information for product comparisons. Heavily fabric reinforced products and non-reinforced films have more consistent puncture values than scrim reinforced geomembranes due to the open structure and thus variability of the reinforcing scrim fabric.

Laboratory Puncture Test Apparatus for ASTM D4833

Laboratory Puncture Test Tips

Stone subgrade and loading on a high puncture resistant XR-5 Geomembrane sample

Stone subgrade and loading on a high puncture resistant XR-5 Geomembrane sample

Some engineers specialize in geosynthetic projects, while many are required to specify and design a geomembrane system infrequently. With all the noise in the industry, it is important to focus on the top properties and then look at the rest. Consider how well the essential properties align with the project requirements.

All photos are from Seaman Corporation.