The terms attachments, penetrations and terminations are often considered synonymous, or at least in the same family, when used in the context of geomembranes. This post will focus on attachments and specifically a review of ASTM D6497, one of the main guides for geomembrane mechanical attachments.

ASTM D6497 (General Practices for Geomembrane Mechanical Attachments) is a broad, comprehensive look at standard methods of mechanical attachments. Beyond the data that is presented regarding the state of the practice in geomembrane mechanical attachments, there are various points noted for consideration to achieve successful attachments, including the following:

- Welding geomembrane pipe boots to the base geomembrane for pipe penetration <45° to the surface is more difficult.

- Gaps between rondels (embedment) strips must be considered. The absence of gaps with complete prefabrication is desirable but typically not feasible.

- Direct welding of any thermoplastics to each other is possible. Note: This is a concept that is contradicted in the literature including Koerner, R.M., GMA Techline, June 2015.

- Boots, corners, and edges prefabricated in a controlled factory environment are considered higher quality than those manufactured in the field.

An important portion of the standard directly identifies critical areas for protection of geomembranes:

- Surface characteristics (the surface to which the geomembrane is to be attached).

- Edges of structures.

- Large voids under geomembranes.

- Settlement around structures (and thus around attachments).

- In-plane attachments becoming out-of-plane.

- Protection from bolts, battens and clamps.

- Cushion/sealants between geomembranes and surfaces, geomembranes and battens, and geomembranes and clamps/bonds.

How can you use this information, both recommendations and areas of concern, to select and design the proper geomembrane system? The standard makes no obvious mention of geomembrane types, polymers or brands, but here are five basic considerations to best utilize the information presented in ASTM D6497.

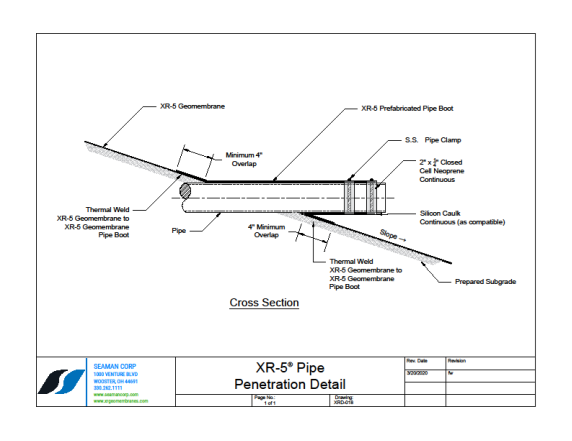

- Keep penetrations at a >45° angle. Utilize prefabricated pipe boots. If available, use preformed inside/outside corners, all constructed of the same polymer as the parent liner. Do not attempt to weld dissimilar materials, even thermoplastics, without proper testing.

Geomembrane Pipe Penetration Sealing Detail

Installed Pipe Penetration Seal to XR-5 Geomembrane.

Oklahoma, USA

Preformed XR-5 Geomembrane Pipe Boots - Utilize flexible reinforced geomembranes which can:

- Bend around edges.

- Span small voids.

- Provide adequate tensile strength against skin friction induced from settlement.

- Have low elongation with loading.

XR-5 Geomembrane folded and wrapped around Geofoam.

Ohio, USA - Utilize low thermal expansion-contraction thermoplastic geomembranes like the XR-5 Ethylene Copolymer from Seaman Corporation, to eliminate problems, or even concerns, with differential temperatures, creating stress points at attachments. This is also true of thermal movement induced from temperature changes with curing concrete.

Low Thermal Expansion-Contraction

XR-5 Geomembrane. Air temperature 33° C (92° F).

Oklahoma, USA - In-plane loading effectively utilizes the full tensile strength of a geomembrane. In some situations, a continuous in-plane load is applied such as hanging clearwell curtains in a potable water application. To hold the in-plane loading, use a geomembrane with heavy internal reinforcing, bonded to the environmentally resistant polymer coating, providing:

- High Modulus (Load/thickness relative to elongation at yield).

- High Yield strength.

- Seam Strength ≥ sheet strength.

Hanging Clearwell Curtain. XR-3 PW Geomembrane

California, USA

- Abrasion, because of contact with protrusions or other rough surfaces, can occur with geomembranes during deployment and even in service, after the attachments are secured. As outlined in the ASTM standard, geotextiles are often used to cushion or provide protection for the liner. Use a geomembrane with robust physical characteristics such as the XR-5 geomembrane to further protect against abrasion and punctures, and has the highest survivable properties.

XR-5 Geomembrane being deployed directly over aggregate

Druid Hills Reservoir. Baltimore, Maryland

USA

XR-5 Geomembrane being deployed directly over aggregate

Oil Spill Cleanup, Biloxi, Mississippi

USA

Take advantage of ASTM D6497 and select/design geomembranes which address potential problems identified in the standard.

To learn more about the XR-5 series of geomembranes, visit www.xrtechnology.com.

All photos are sourced from Seaman Corporation.