Effective planning and management of bulk petroleum storage tanks are critical to environmental protection. To contain potential spills and leaks, these tanks must be surrounded by berms—usually earthen, if configuration allows. Some engineers may not be aware of the compelling reasons geomembranes can be the best and most cost-effective choice for secondary containment. Other options occasionally considered are:

• Asphalt, either hot mix or cold applied mats

• Concrete, either poured in place or premade uncured mats

• Spray-on systems, either direct to subgrade or on applied substrate

Storage facility lined with the XR-5® Geomembrane by Seaman Corporation

Storage facility lined with the XR-5® Geomembrane by Seaman Corporation

Source: Bright Mark Energy

Federal regulations around secondary containment—and, more often, local regulations—can be a bit vague. On one hand, this gives owners and their designers the versatility to be innovative. On the other hand, however, to meet the objectives of secondary containment, the primary spill control barrier must meet basic criteria. These include:

1. Long-term chemical resistance. This enables prevention of a long-term seep, which is critical because some amount of petroleum will likely always be present, even after a spill cleanup.

2. A rugged, engineered system. The system should enable proper installation and must be functional from a strength standpoint.

3. Constructability and reliability. These characteristics ensure systems can be built to precise specifications and that they will perform once in service.

Seaman is a pioneer in the lining industry and has amassed extensive data about these types of projects. Data shows that geomembranes are the best overall solution for containing spilled petroleum products. Here’s why:

Weight. Geomembranes, on a unit basis, are the lightest and least-bulky weight option for providing secondary containment, making them easier to handle and install.

Perm/Absorption. Geomembranes offer a range of perm/absorption options and can meet the precise specifications of the application. Reinforced, flexible, hydrocarbon-resistant geomembranes are the better option for secondary containment. Asphalt and concrete—either field-constructed or premade sheets—have permeability values much closer to clay. They absorb water and would also absorb fuel. Water permeability usually does not equal hydrocarbon permeability. Spray-on products can have very low perms, if totally encapsulated (see information about reliability below).

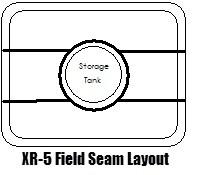

Ease of installation and cost. The constructability of the selected secondary containment system is an important consideration. Can it be properly installed to ensure it will fulfill its designed purpose for its intended design life? Prefabricated geomembranes offer the simplest installation and are the most cost-effective alternative when considering initial cost and lifecycle. The diagram below, which represents typical prefabricated geomembrane panels and the resulting field seams, illustrates the minimal field seams required for geomembranes installation.

Source: Seaman Corporation

Source: Seaman Corporation

Long-term connections. Geomembranes are securely attached and, if designed correctly, deliver long-term stability. Concrete, concrete blankets and asphalt require water stops and, as a result, add potential leak points. Spray-on systems are heavily dependent on the operator and lack factory-level quality control. In fact, one could say the entire system is manufactured in the field.

Reliability. Asphalt and concrete are subject to cracking and require coating. Spray-on liners are unreliable when it comes to the thickness of polymer applied, condition of joints and the variability of installation climatic conditions. Concrete mats are manufactured to final use in the field. Geomembranes are the only alternative manufactured in a controlled environment and subject to strict quality control.

Weathering. Geomembranes weather well, and because some have low thermal expansion/contraction properties, they are thermally stable.

Workability. Generally, geomembranes require less maintenance, and repairs are easier to complete without compromising performance. Repair and maintenance of secondary containment built with other materials can be bulky and costly.

When planning secondary containment for bulk petroleum storage tanks, consider both short- and long-term needs. Selecting a rugged, engineered system that offers constructability, reliability and long-term chemical resistance is the key to effectively containing potential spills and leaks. Geomembranes, such as XR-5®, can offer proven long-term advantages.

Diesel fuel secondary containment system using XR-5 Geomembrane

Diesel fuel secondary containment system using XR-5 Geomembrane

Source: Google Earth