Kingsley Field in Oregon Uses Seaman XR-5 for Fuel Tank Containment

Application Snapshot:

Installation: Kingsley Field ANG Secondary Fuel Containment

Location: Klamath Falls, Oregon

Purpose: Secondary Fuel Containment

Owner: Oregon Air National Guard

Solution: XR-5® Geomembrane by Seaman Corporation

Engineer: Tetra Tech

Fabricator: ACF West

Installer: ACF West

Date Installed: October 2020

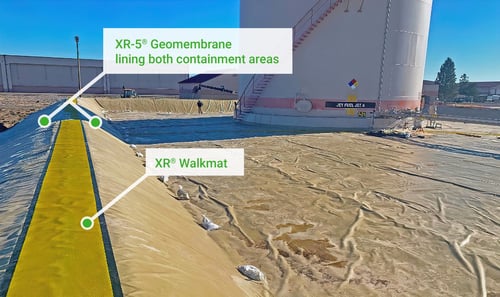

Kingsley Field ANG Secondary Fuel Containment Photo Credit: ACF West

An essential operation

Located just southwest of Klamath Falls, Oregon, Kingsley Field is operated by the 173rd Fighter Wing of the Oregon Air National Guard. It supports combat operations as a training facility for F-15 Pilots and has served the State of Oregon since the late 1970s.

Kingsley Field, Photo Credit: KDRV.com

Google Earth image of above-ground jet fuel storage tanks at Kingsley Field

Two above-ground jet fuel storage tanks supply fuel for base operations. These tanks are vertical hard-shell construction and have been in service since at least 1994. In compliance with spill prevention, control and countermeasures (SPCC) regulations and requirements found in Title 40 of the Code of Federal Regulations (CFR) Part 112, earthen berms surround the tanks, providing the required 110% spill volume capacity.

Each tank is contained in its own bermed area, approximately 200 feet by 175 feet (61 m x 53 m) and 110 feet by 135 feet (34 m x 41 m). The SPCC regulations also require that the containment areas must be “sufficiently impervious to contain oil,” which broadly states the need for compatibility with the stored liquid.

HDPE liner, Photo Credit: ACF West

A need for containment

In recent years, Kingsley installed a white high-density polyethylene (HDPE) liner around the tanks for containment. Recognizing the advantages of not placing ballast over the liner, the owner opted to leave it exposed. But because HDPE has a high thermal expansion/contraction rate, coefficient of thermal expansion (CTE), the fixed connections— like perimeter battening—experienced damage and required frequent maintenance, resulting in breeches and ultimately requiring replacement of the liner.

Elevated specifications

To maintain regulatory compliance, the consultants from Tetra Tech Engineer specified a Seaman Corporation XR-5® replacement geomembrane because it met these critical criteria:

- It can withstand an uncovered application. Seaman XR-5 was designed to be UV-exposed and still maintain the stability of the military color. Kingsley desired the lower maintenance requirements, optimal initial cost and efficient operating expenses inherent with a non-ballasted geomembrane.

- It possesses very low thermal expansion characteristics. Because of the first requirement, the CTE had to be negligible. While a lighter color lowers the temperature variation, it does not change the actual CTE. Noncrystalline geomembranes, such as ethylene copolymers, have CTE values that are an order of magnitude lower than crystalline materials like HDPE.

- It delivers proven long-term jet fuel compatibility and low jet fuel permeability. Specific long-term compatibility data was integral to demonstrating the true fuel resistance. And specific permeability data was essential for containment assurance.

XR-5 applied for secondary containment, Photo Credit: ACF West

- It has high puncture resistance and low field seaming requirements. The rigors of installation and operation demanded high puncture resistance, which is provided by the specified geomembrane. To minimize the time of installation, large panels were specified to minimize field seaming. Not only did this simplify installation, but it will also provide greater long-term containment integrity. In fact, field seaming requirements were approximately one-third that of rigid film products such as HDPE.

A solution that aligns with the precise needs of the base

Both containment areas were lined with the Seaman XR-5 Geomembrane in a continuous fashion—the liner was not terminated on the common dike, but rather it also lined the dike. To provide operational flexibility, a walkmat was placed on the crest of the dike. The walkmat also uses the Seaman XR-5 Geomembrane, but with a gritted surface to allow the underside to be welded directly to the parent liner. This provides a stable system that will deliver on the goals of low maintenance and ease of operation for the air base.

Extremely low permeability to jet fuel combined with a rugged product, the 65,000 square feet (6,000 square meters) of Seaman XR-5 Geomembrane will provide containment assurance to Kingsley for many years to come.

To explore the technical data that helped demonstrate the product fit for this application, download our Geomembranes Tech Manual.