Wastewater Series: How Geomembranes help to improve water quality, lower costs and increase efficiencies in wastewater treatment

Part 2: Wastewater Treatment Processes

“We forget that the water cycle and the life cycle are one.” Jacques Yves Cousteau

In Part 1: “Wastewater Industry in North America”, a brief history of the efforts to deal with wastewater was explored along with estimates of the size of the industry itself. In this post, we will take a look at the current techniques used to manage wastewater which can be considered as three parts: Collection and Equalization, Treatment and Residuals Management.

Wastewater Treatment Plant with Flow Equalization Basin.

Wastewater Treatment Plant with Flow Equalization Basin.

Batesville, IN USA

Collection and Equalization. With the exception of combined systems, most sewage collection systems are not designed to carry stormwater. Rather, they are sized primarily based on estimates for the amount of wastewater generated per capita which varies between 60 and 100 gallons per day (gpd), with 100 gpd being a common design standard. Most collection systems do, however, carry large quantities of stormwater, in addition to domestic wastewater, resulting in overloaded collection and treatment systems during storm events. Many systems utilize sanitary sewer overflow (SSO) or flow equalization holding ponds/tanks upstream of the wastewater treatment plants (WWTP), or Water Resource Recovery Facilities (WRRF), for hydraulic detention, to prevent release of untreated wastewater.

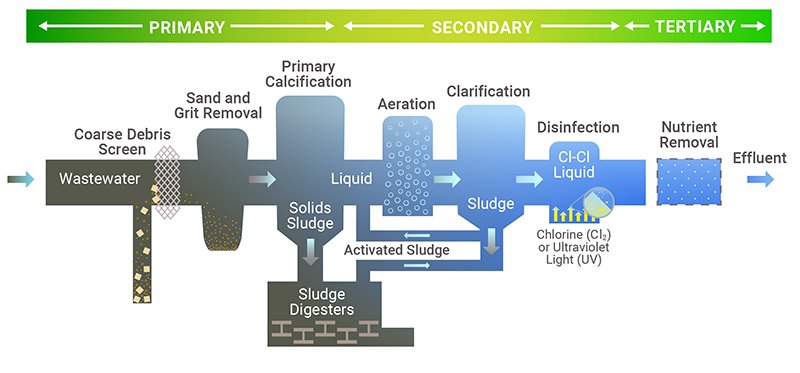

Treatment Processes. Typical wastewater treatment processes are classified by level of treatment in 3 categories which progressively improve the quality of the wastewater:

- Primary Treatment – These processes are physical unit operations such as bar racks and screens which separate coarse solids from incoming wastewater. Without primary treatment, damage can occur to other downstream processes.

- Secondary Treatment – Secondary treatment is a broad category and has been the core of most treatment processes since the passage of the Clean Water Act. It consists of physical unit operations such as solids separation and the biological and/or physical-chemical removal of soluble organics in processes which include: Primary Clarification (also used as a primary treatment process)

- Activated Sludge

- Bioreactors

- Fixed Growth Biological Systems

- Secondary Clarification

- Disinfection.

These categories are broad, and some are often components of others.

While disinfection (various chemicals and processes in addition to Chlorine gas) is normally the last step in treatment prior to discharge, it is often considered a necessary process prior to Tertiary treatment to prevent biological fouling. Facultative ponds have been known to achieve secondary treatment levels but are not always regulatory permitted as such due at least partially to their lack of operational control. Those impoundments use both aerobic and anaerobic processes for digestion of organic matter.

Typical Activated Sludge Treatment Process Components

- Tertiary Treatment – Advanced or Tertiary treatment provides treatment beyond that provided by secondary treatment. It is often targeted treatment in that it seeks to remove, or alter, specific components. Advanced Treatment processes include:

-

- Ion Exchange

- Activated Carbon Adsorption

- Reverse Osmosis, Ultrafiltration

- Anoxic processes

- Chemical coagulation and clarification/filtration

Some processes can be considered secondary and/or tertiary such as Anoxic processes which modify the aerobic levels of Activated Sludge to achieve both organic reduction and nutrient removal.

Natural processes like facultative ponds (aerobic-anaerobic) were followed in technology by fixed growth systems (trickling filters). In the 1960’s, activated sludge systems gained popularity due to their larger hydraulic capacity and ability to lower organic and solids contents to secondary treatment standards. Today, activated sludge systems modified to achieve better solids separation, enhanced nutrient removal, lower energy requirements, and other improvements are widely used, often coupled with anaerobic processes.

Residuals Management – Solid byproducts are generated by wastewater treatment processes. The largest volumes result from biological treatment and are in the form of high-water content, biologically active solids, or sludges. Further treatment is commonly achieved in an aerobic or anaerobic digester, followed by mechanical dewatering. Anerobic digestion can also be used to treat the entire liquid waste stream prior to secondary treatment in the case of very high organic loading from certain industries. These digestors typically have floating geomembrane covers.

Geomembranes play a vital role in many parts of the wastewater management system which will be discussed in the next 2 posts of this series.