What are the Major Neglected costs in your Geomembrane Installation?

Two Part Blog:

Part 1: 4 Commonly Identified Geomembrane Costs

Part 2: Quantifying Additional Geomembrane Installation Costs

Part 1: 4 Commonly Identified Geomembrane Costs

In late 2019, we posted a blog on the source of geomembrane installation costs. Note from the title of the post that there are major considerations beyond the costs to get to the point where the geomembrane goes into service as a containment barrier. In other words, there is a difference between initial and lifetime costs.

To take it a bit further, there is a difference between the initial cost of the geomembrane itself and the costs associated with the system, both initially and long term.

XR-5® lined wastewater Impoundment, Sonoma, California, USA

XR-5® lined wastewater Impoundment, Sonoma, California, USA

Source: Seaman Corporation

The 2019 blog considered four cost components of an installed geomembrane:

- Material—Sheet goods, which include the cost of factory fabrication if possible and shipping to the job site and/or fabrication plant.

- Installation—Layout of prefabricated panels or factory rolls, if rigid geomembranes are used. Field-seaming and perimeter attachments are included.

- Construction Quality Assurance (CQA)—Cost of assuring a successful installation, primarily testing of field seams.

- Geotextile—Typically required for added puncture resistance needed to enhance what is provided by nonreinforced or lightly reinforced geomembranes, dependent on subgrade and operational conditions.

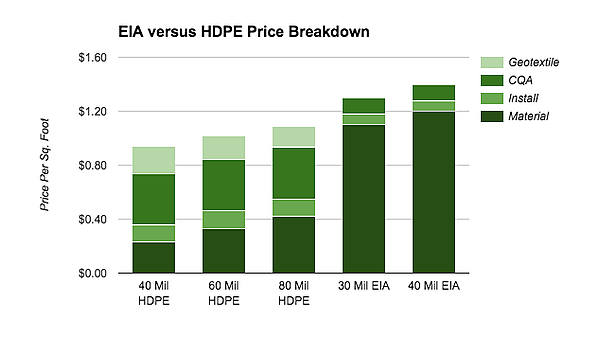

XR-5® by Seaman Corporation at two thicknesses, and a blown film polyethylene product, high-density polyethylene (HDPE) at three different thicknesses. Note the costs are intended to be representative only and are based on 2019 conditions.

The chart shows each of the four components in a cumulative manner to reach a total installed cost per square foot. Obviously with such different geomembranes, there are performance differences, but this is simply a cost comparison.

By looking at the individual cost components, one can conclude which products generally have a cost advantage and why:

- Sheet material—Start with a cheaper polymer. ADVANTAGE: HDPE

- Installation—Flexible geomembranes can be made into large panels, with minimal field seams. ADVANTAGE: XR-5®

- Construction Quality Control—Fewer field seams, less CQA. ADVANTAGE: XR-5®

- Geotextile—Lower puncture strength products may appear to be cheaper but must be supplemented with geotextiles for puncture resistance. ADVANTAGE: XR-5®

The overall conclusion of this broad cost analysis implies that if compared as commodities, the HDPE film is less expensive initially. However, geomembranes are not commodities, so their performance differences must be considered vs. the project requirements. Maintenance and reparability impact lifetime costs as well. Additionally, some polymers require much more engineered protection for their use in geomembrane systems and additional capital costs.

Part 2 of this blog series will take a deeper dive into additional initial project costs incurred when using certain geomembrane systems.

For a technical comparison of XR-5® and HPDE films, view our comparison of XR Geomembranes vs. HDPE Geomembranes.