Three-Part Series: Understanding and ensuring proper geomembrane chemical resistance

Knowing the importance of chemical resistance data, how do you know what the most reliable information is?

There are five ways to ensure.

- Know your secondary containment requirements. We often receive inquiries regarding a mixed waste stream or static liquid containment project that is only partially defined. It is critical to know as much as possible about the liquid in terms of chemical contact, temperature, reactions expected to occur within the containment, etc., to properly contain it. You also need this information to design a treatment process. Data out is only as good as the data in.

- Manufacturer’s data. The easiest and perhaps the best way to understand chemical compatibility is to look at validated manufacturers’ data. Note the word “validated,” which means test data, not assumptions (see more in no. 4 below and Part 2 in this series ). If validated data is available, it represents a high level of assurance for compatibility.

- Look at the chemical structure of the polymer and the construction of the membrane. Simply put, some polymer systems should not be used with certain liquids. An example is plasticized PVC that should not be used with petroleum. Plasticizer is an oil and will be miscible with the contained liquid. Some polyethylene should not be used with wetting agents, such as surfactants, because they can be damaged due to the nature of the crystalline polymer structure. Don’t forget that permeability is not always proportional to chemical resistance, which I will cover in an upcoming blog. In short, look closely at the polymer structure.

- Test immersions are very important. Ideally, a field that is in situ immersion using geomembrane coupons that are ultimately lab tested after the immersions is the best way to simulate actual application conditions, particularly when it comes to variations in temperature, contact time and actual waste stream components.

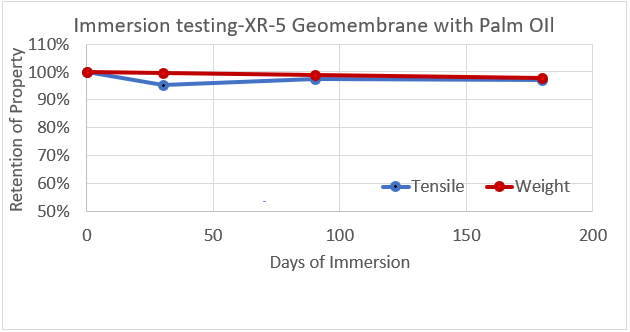

In lieu of a field or bench scale test, laboratory immersions are helpful, particularly when dealing with pure solutions. These photos show a laboratory water bath that maintains a constant temperature for liquid and membrane samples. Samples can be retrieved and tested to evaluate changes in mechanical properties. While 30-day data is usually sufficient, it is often advantageous to evaluate longer trends as shown in the below graph for the XR-5® Ethylene Copolymer geomembrane in contact with palm oil. Little change in properties and/or stabilization of minor change is indicative of good long-term compatibility.

Laboratory Water Bath

Laboratory Water Bath

Source: Seaman Corporation

- Test immersions are very important. Wait, didn’t we just cover that one? Life is great and you have it figured out, and then you are tasked with treating and containing a mixed waste stream. It is very common. A field test immersion is the best (or only?) method of ensuring a geomembrane is compatible with a heterogeneous liquid. To even out variabilities, 30 days is considered a minimum, and longer immersions are warranted based on the complexity of the process generating the liquid.

Chemical Resistance Is Important

Chemical Resistance Is Important

XR-5 Geomembrane Process Wastewater Impoundment, Qatar

Source: Arabian Environmental

The bottom line is that to make a proper decision, it is important to understand and validate geomembrane chemical resistance data.

For more information on the XR® series of geomembranes, go to our website.