Potable Water Series: How Geomembranes Help to Improve Quality, Lower Costs and Increase Efficiencies in Water and Wastewater Treatment

Municipal water and wastewater systems are considered to be one of the costliest assets for municipalities to maintain. Potable water safety and quality is not only a priority, but it is also a highly regulated necessity. In this four-part series, we’ll cover drinking water treatment processes, water sourcing, water distribution and how geomembranes can help improve quality, lower costs and increase efficiencies.

Part 2: Geomembranes in Drinking Water Treatment Processes

“If there is magic on this planet, it is contained in water.”

Loren Eiseley

In “Part 1: Drinking Water Industry in North America,” a brief history of the treatment of drinking water was explored along with an overall look at the industry itself. In this post, we’ll examine treatment processes. The supply of potable water to users can be broken down into three parts: Source water, drinking water treatment system, and the finished water distribution system.

Source. Most of the raw drinking water in the United States and Canada comes from surface supplies, such as rivers and lakes with the remainder primarily from groundwater. Often, to ensure year-round availability, surface waters are diverted to holding ponds or water storage tanks from the original source.

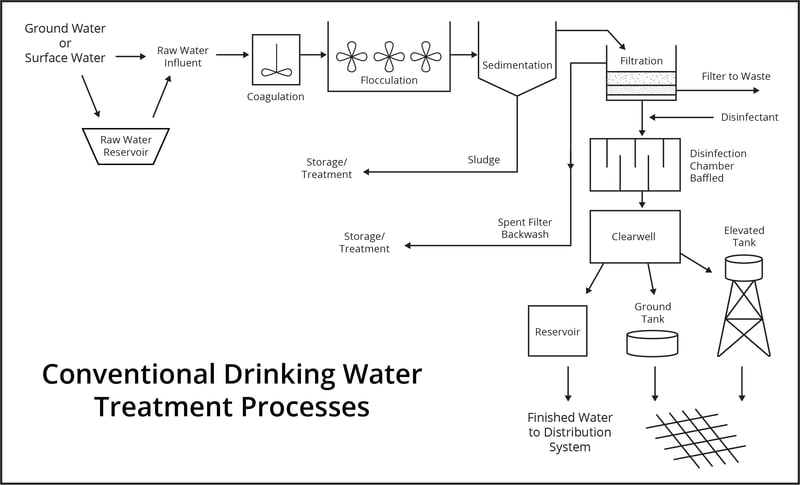

Treatment. Many water treatment plants use a conventional treatment technique, which is a combination of coagulation, sedimentation, filtration and disinfection. These treatment methods represent the most widely applied technology worldwide and have been the basis for water treatment for many years. The major steps in treatment are:

Screening – Removal of coarse particles to protect the downstream processes.

Chemical introduction for removal of solids, dissolved metals – There are many options in this step, and some can even involve aeration, which is a method of introducing oxygen to oxidize iron from a soluble form to an insoluble form to allow removal. In the precipitation process, coagulants (often Alum or Aluminum Sulfate) are used to bring together particles for ultimate enlarging in the subsequent flocculation step. Additional chemical feed enhances the efficiency of the particle removal.

Whitaker Water Treatment Plan, Knoxville, Tennessee

Photo Credit: Knoxville Utilities Board

Water softening, a chemical process to primarily remove calcium and magnesium, is also sometimes used. Softening improves the taste, quality and usability of the water but also produces additional waste byproducts that require storage, handling and, ultimately, reuse or disposal.

Settling and filtration of precipitated solids – After the coagulation and flocculation step, the pollutants have been converted to larger solids and can be removed by settling and filtration. Settling often precedes filtration to give longer run time before head loss in filtration requires the filters to be taken out of service and backwashed. Backwash is normally sent to holding ponds or tanks. Filtration media can be granular or can be an enhanced media such as activated carbon for additional organic removal.

Tertiary removal of organics and metals – The most widely used processes include ion exchange and activated carbon adsorption. The use of these advanced techniques is becoming more widespread as concern has grown over selected pollutants in drinking water. More recently, the health effects of per- and polyfluoroalkyl substances (PFAS) have been discovered, driving emphasis on their removal from drinking water.

Disinfection – Chlorination continues to be the dominant method of disinfection although there are some variations in the Chlorine compounds used. Also, UV light and Ozone are alternate methods. Each type of disinfection has advantages and disadvantages, depending on the source water and other considerations.

Conventional Drinking Water Treatment Processes

Source: Oregon Health Authority, Surface Water Treatment (modified)

As a final treatment step, fluoridation is quite common, and depending on the type of distribution piping, corrosion inhibitors are also added.

Distribution – After final treatment, the water enters a storage area usually referred to as a clearwell. Additional storage is normally required to have sufficient water available for diurnal demands, along with firefighting. Ground level tanks with either fixed or flexible geomembrane roofs, above ground potable water storage tanks and in-line standpipes are all types of storage facilities used. The piping distribution systems are typically very complex in order to manage pressures necessary to reach many different areas in terms of elevation and distance.

Above Ground Water Storage Tank

Photo Credit: Adnan from Pexels

Underground potable water storage tank covered with a Geomembrane Floating Cover

Underground potable water storage tank covered with a Geomembrane Floating Cover

Seaman Corporation Photo

After such a careful, complex process for sourcing and treating water, safe storage before distribution is a critical consideration. Geomembranes can play a valuable role that we’ll explore in the next part of this series.

Next up, Part 3: Geomembrane Applications in Sourcing and Treatment