Within the Mobile Area Water and Sewer System (MAWSS) is the Dog River Watershed that encompasses a substantial portion of the city. Much of it is a natural wetland and contains tidally influenced marshes that support various species of shellfish, birds, finfish and other wildlife. One of the major tributaries to the Dog River is Halls Mill Creek.

Sanitary Sewer Overflow. Source: AL.com

Sanitary Sewer Overflow. Source: AL.com

Like most cities, Mobile, Alabama’s, sewage collection system has sanitary sewer overflows (SSO’s). Sanitary sewers are not designed to carry storm water, but usually act as de facto combined sewers due to the intrusion of surface water during rain events.

The results are overloaded pipes, pump stations and treatment plants. The obvious solution would be to remove the extraneous water sources, but that is very expensive and might even be impossible for a number of reasons. (More detail on another city’s SSO problems and solutions can be found here.)

Click to watch an overview of the project.

Gravity sewer systems make use of natural topography, so wastewater flows within a given watershed and reaches high volume at the lower end, typically where the elevation is at its lowest point. That is one of the most critical points in the collection system, although it is important to note that SSOs can occur within the collection system at intermediate points.

Sanitary Sewer Overflow Flooding. Source: AL.com

The challenge:

The Halls Mill Creek lift station is at the lowest elevation in a sub basin within the MAWSS sewage collection system and was subject to large SSOs spilling wastewater that would make its way to Halls Mill Creek and the Dog River. One tropical storm alone caused an estimated 9 million gallons of wastewater to overflow into the creek. The lift station is a major component of the wastewater collection system, servicing a large portion of western Mobile.

The solution:

MAWSS employed CH2M Hill (now Jacobs Engineering Group) to design a solution. As mentioned earlier, repairing or eliminating the stormwater intrusion for a city the size of Mobile that has 3,200 miles of sewer lines can take decades, cost hundreds of millions of dollars and not be totally effective.

SWAB Construction. Source: AL.com

SWAB Construction. Source: AL.com

The solution was to construct three earthen basins officially known as Severe Weather Attenuation Basins – or SWAB. The basins store excess collection system flow which, after a wet weather event, feed back into the system for treatment prior to release.

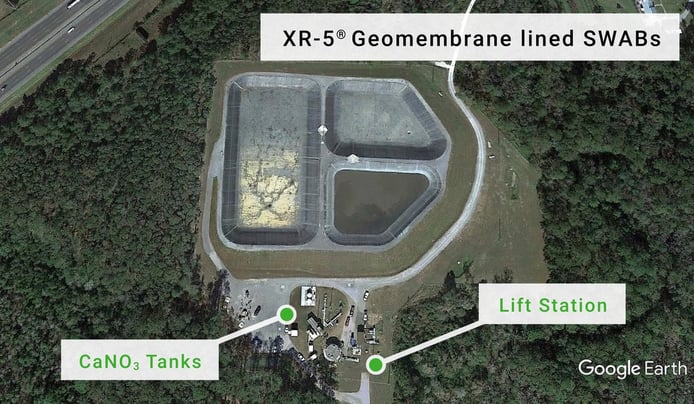

The size, number and configuration of the basins maximize available space on the 12-acre site that is adjacent to the Halls Mill lift station, providing combined storage volume of 19 to 20 million gallons. Trailer mounted pumps are automatically activated when inflow begins to exceed lift station capacity, which then sends excess flow into the SSO basins.

How geomembranes were incorporated into the project:

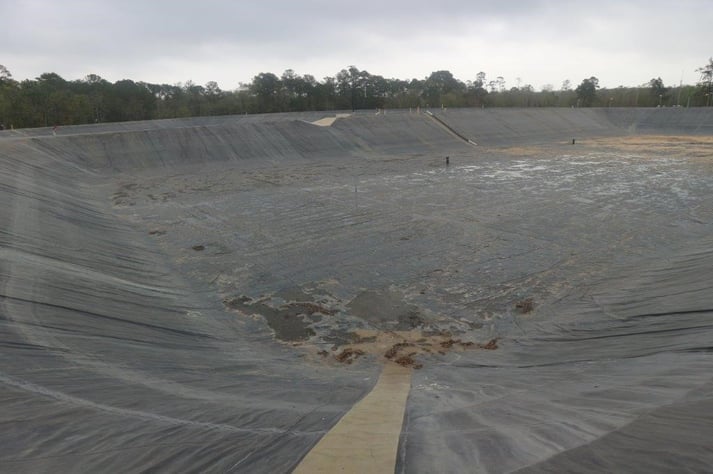

CH2M Hill recommended using a geomembrane liner in the basins for several reasons, including retention of wastewater and ease of cleaning. The specification called for the 8138 XR-5® geomembrane, a reinforced ethylene copolymer with high strength and UV resistance. Due to its very low thermal expansion/contraction properties, it did not require protective earthen or granular cover. CH2M Hill used 313,000 square feet of XR-5® for the three impoundments.

Prefabricated XR-5 Panels. Source: Colorado Linings

Prefabricated XR-5 Panels. Source: Colorado Linings

Because the geomembrane is flexible, it was prefabricated into large panels that minimized field seams. These panels were 12,000 square feet, greatly simplifying installation and ensuring reliability.

XR-5 Geomembrane Installation at Completion. Source: Seaman Corp.

XR-5 Geomembrane Installation at Completion. Source: Seaman Corp.

XR-5 Lined SSO Basins at Halls Mill Creek. Source: Google Earth, 2020

XR-5 Lined SSO Basins at Halls Mill Creek. Source: Google Earth, 2020

Due to the high groundwater table, the impoundments were constructed so that the bottoms would be above the seasonal high groundwater level. In fact, the tops of the slopes were 20 feet above adjacent access roads. This also allowed gravity to force the excess flow back into the lift station wet well for pumping to the treatment area and further minimize back-pressure uplift concerns. The basins’ inlet/outlets were in the center of the basin sloping from an elevation of 10 feet mean sea level (MSL) to 8 feet MSL to facilitate cleaning.

Note this is an underwater connection between the XR-5® geomembrane and the outlet pipe. Underwater connections are common but extra care must be taken by the installer to ensure a leakproof fit. The XR-5® is very dense, exceeding a SG of 1, making an underwater connection more reliable than other geomembranes.

To maximize storage capacity, steep side slopes at a 2:1 ratio were used so that no cover was required. If the liner required protective overburden for long-term use, the slopes would have necessitated a flatter profile, loosing volume in the impoundments on this very tight site.

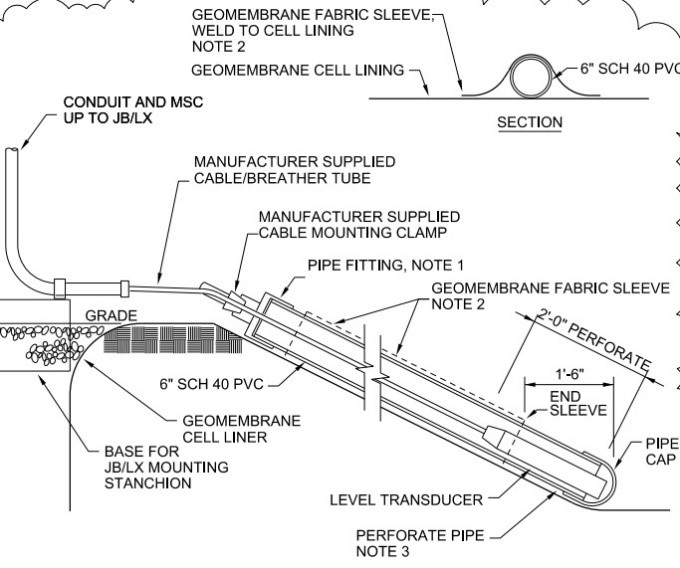

All three basins were equipped with level sensors to maximize storage space while preventing overflows. They are encased in PVC pipe and anchored to the parent material with straps made of the XR-5®.

Basin Inlet/Outlet. Source: Seaman Corp.

Basin Inlet/Outlet. Source: Seaman Corp.

Transducer Design. Source: CH2M Hill

Transducer Casing. Source Seaman Corp.

Transducer Casing. Source Seaman Corp.

Liquid calcium nitrate is added to the wastewater as it is pumped to the basins for temporary odor control during the open storage of the dilute wastewater. While this increases nitrogen

load on the treatment process, the CaNO3 reacts with hydrogen sulfide to minimize odors during the storage process.

In the Google Earth depiction above, Interstate 10 is in the upper portion. The project has a lot of close neighbors, so MAWSS and CH2M Hill wanted a complete system to manage these overflows, including a reliable geomembrane containment system. Without using a geomembrane with negligible thermal expansion-contraction, a granular cover would have been required, allowing organics to remain in the basin after the wet weather event – which would have resulted in inevitable odor generation.

Water Cannon. Source: Seaman Corp.

Water Cannon. Source: Seaman Corp.

The overflow entering the basins is very dilute, so they are primarily self-cleaning, but manual high-pressure cleaning with municipal water is used with fixed water cannons as required. Note at the Haikey Creek overflow basins (linked above), the operators have found that manual cleaning is required on an infrequent basis. Again, not needing to be covered to protect it against thermal stresses, the XR-5® geomembrane allows complete cleaning with no odor-generating residuals.

Overflow spillways. Source: Seaman Corp.

Overflow spillways. Source: Seaman Corp.

The basins were connected with overflow spillways located slightly above the maximum water level at the lower point of freeboard. While the ponds are operated independently, this provided an additional safety factor against overflows. Embedment strips made of the XR-5® compound were cased in the concrete spillways, allowing the parent liner to simply be welded for a secure connection to the concrete.

For safety during maintenance activities in the basins, a gritted walkmat was used to give personnel stability on the slopes. The walkmat uses the XR-5® geomembrane as a substrate with a gritted surface. Because it is the same as the parent liner, it can be welded to the liner, thus providing anchorage. Standard top-of-slope vent flats were installed for the prevention of uplift.

XR Walkmat. Source: Seaman Corp

XR Walkmat. Source: Seaman Corp

The storage capacity of the basins also support ongoing modifications to the CC Williams Wastewater Treatment Plant which will reduce flow equalization storage by 10 million gallons temporarily during plant upgrades. Further, these basins allow operational flexibility for maintenance on the Halls Creek Lift Station. The basins have been operational since early 2018. An inspection of the XR-5® geomembrane in April 2021 indicated the material was performing well, had low maintenance requirements, and was supporting the SSO abatement program by MAWSS.

Finished XR-5 lined SSO Basin. Source: Seaman Corp.

Finished XR-5 lined SSO Basin. Source: Seaman Corp.

Finished XR-5 lined SSO Basin. Source: Seaman Corp.

For more information, visit our website.