Potable Water Series: How Geomembranes Help to Improve Quality, Lower Costs and Increase Efficiencies in Water and Wastewater Treatment

Municipal water and wastewater systems are considered to be one of the costliest assets for municipalities to maintain. Potable water safety and quality is not only a priority, but it is also a highly regulated necessity. In this four-part series, we’ll cover drinking water treatment processes, water sourcing, water distribution and how geomembranes can help improve quality, lower costs and increase efficiencies.

Part 4: Geomembrane Applications in Potable Water Disinfection and Distribution

“Now that’s what I call high-quality H2O.”

Bobby Boucher, “The Waterboy”

In part 3 of this series, we explored the use of geomembranes for the source water portion of the drinking water process through the actual treatment, up to the point where disinfection occurs. Disinfection is generally thought to be the final step in the treatment process. The steps we’ll review here include disinfection and distribution.

Disinfection of Potable Water

The American Water Works Association states, “Disinfection is a required step in drinking water treatment that is enforced to protect public health.” It is usually the last step in improving drinking water before it is consumed. Let’s take a closer look at the disinfection process.

Baffling during disinfection. The efficiency of a disinfection process is highly dependent on contact time between the disinfectant, often chlorine, and microbial pathogens. A disinfection chamber—a holding vessel or tank—allows for controlled contact time. Short circuiting is a major concern, so these chambers are usually baffled. A common way to baffle tanks—both new construction and retrofits—is with the use of geomembrane baffles. Baffles hang vertically, necessitating the use of high-modulus, reinforced materials such as the XR Series of potable water geomembranes. Additionally, proper flexible baffle design calls for minimum normal loading on the baffle and favors parallel flow, which utilizes the liquid barrier properties of the geomembrane. High-strength materials also provide assurance of higher performance.

The concentration of chlorine at the point of injection can be high. Geomembranes used for baffling must be resistant to high chlorine levels for extended periods of time. Testing of the XR-5 PW and XR-3 PW Geomembranes has shown no effect with constant contact as high as 15% (150,000 mg/l available chlorine). The actual diluted concentration for drinking water is closer to 6 mg/l. A residual amount of chlorine is desirable at the point of consumption.

Data about the XR-5 PW and XR-3 PW Geomembranes’ chemical resistance to various levels of chlorine and hypochlorite is available for review here.

Additional baffling can be incorporated immediately after chlorination in a clearwell storage chamber, which allows additional control of contact time from chlorination. Fixed geomembrane baffles are the most cost-effective way to retrofit existing clearwells to prevent short circuiting.

Clearwell potable water flow comparisons

Source: Environetics.com

Clearwell potable water flow comparisons

Source: Environetics.com

Using XR-5 PW and XR-3 PW Geomembranes for the complete lining of the completed wetted area in clearwells and storage tanks preserves the tank surface from adsorption/leaching and simplifies maintenance.

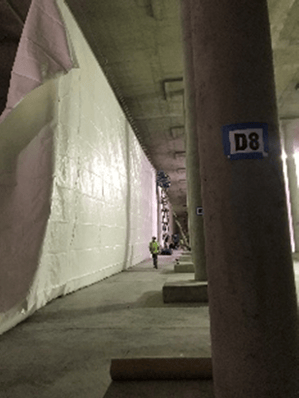

Clearwell lining with white XR-3 PW in Burlington, Vt.

Clearwell lining with white XR-3 PW in Burlington, Vt.

Source: JH Waters Inc.

Finished water storage baffles using XR-3 PW, Columbia, S.C.

Source: Therma Fab Inc.

Finished water storage baffles using XR-3 PW, Columbia, S.C.

Source: Therma Fab Inc.

Potable Water Distribution

Storage of finished water is required in order to bridge the gap between demand and treatment plant capacity. It’s important to balance demand and storage capacity, to effectively utilize treatment plant capacity daily.

There are a variety of options for storage vessels including elevated or ground-level tanks, in-ground tanks with floating geomembrane covers or in-line standpipes. Geomembranes are cost-effective alternatives for flexible covers over finished water impoundments. This storage option requires NSF 61-approved products, which provide long-term weather resistance, have low thermal expansion-contraction properties and can be relied upon for durability.

Finished water storage baffles using XR-5 PW, Miramar, Calif.

Source: Layfield USA

Additionally, an in-ground storage tank requires a geomembrane liner in order to essentially encapsulate the finished water to prevent loss through the bottom—or in the case of evaporation, the top—and maintain purity from the top.

XR-5 PW Floating Cover, Erie, Pa.

XR-5 PW Floating Cover, Erie, Pa.

Source: Seaman Corporation

As with other portions of the treatment process, geomembranes are used as secondary containment barriers for chemical storage. Sodium hypochlorite, for instance, is usually stored in bulk tanks, and geomembranes such as the XR-5 industrial grade or XR-5 PW can serve as a reliable containment option for concentrated chlorine compounds.

XR-5 PW Floating Cover, Port Angeles, Wash.

Source: Layfield USA

Explore the entire Potable Water Series for insight about how geomembranes help to improve quality, lower costs and increase efficiencies in water and wastewater treatment.

Part 1: The Drinking Water Industry in North America

Part 2: Drinking Water Treatment Processes

Part 3: Geomembrane Applications in Potable Water Sourcing and Treatment

Part 4: Geomembrane Applications in Potable Water Disinfection and Distribution