There are pros and cons to either leaving a geomembrane liner exposed (no cover) or burying it (complete cover). Let’s look at the issues.

Geomembrane liners are often used in impoundments to prevent the migration of wastes out of the impoundment to the adjacent subsurface soil, groundwater, or surface water. Impoundment liners are used significantly in the energy industry to contain fresh water and wastewater, drilling waste, evaporation pits, and coal ash. Geomembrane liners used in these types of applications are made from a wide range of polymeric materials and different types of constructions.

How do you choose the right one for your exact application? In order to prevent contamination of the surrounding environment, careful consideration must be given to determine the best high-performance geomembrane liner that meets the precise requirements of the impoundment.

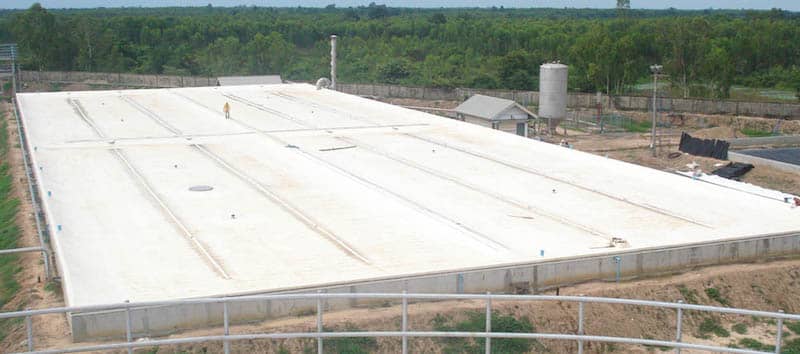

Reinforced geomembranes can be specified in a variety of scenarios, from floating covers to secondary containment liners. Highlighted below are three of the most common reinforced geomembrane applications.

There are many uses of geomembrane liners. They can be used for floating baffles, secondary containment, wastewater impoundments, and more. It’s easy to bypass the important items and make blunders when selecting and specifying a geomembrane. Below are the five biggest mistakes in the selection process and how to avoid them:

When designing a pond or lagoon, preventing leaks is a major concern. However, determining the best geomembrane liner for your project can be an extremely daunting task. You have to decide between reinforced and unreinforced geomembranes, which material and thickness is best, and between a myriad of other physical properties that could play a part in the success of your project. As a result, people oftentimes choose a natural clay liner because it is the less complicated choice.

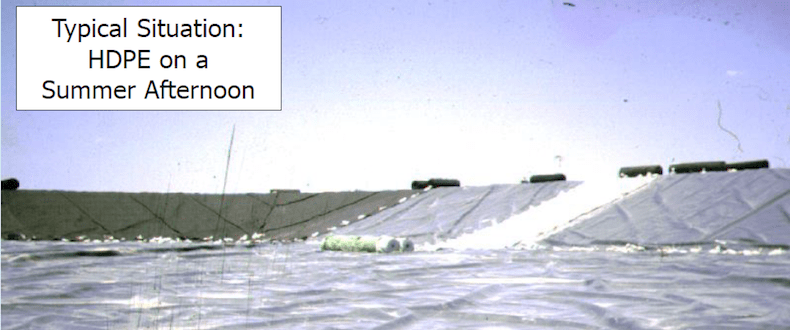

Dr. Robert Koerner, professor emeritus of civil engineering at Drexel University, is a highly respected professional in both the geosynthetic and engineering communities. In his webinar, “Wave (or Wrinkle),” Koerner covers unreinforced geomembranes, such as HDPE, and how geomembrane waves or wrinkles can be somewhat prevented and/or fixed. Here is an overview of the webinar:

For a geomembrane to function properly and protect the environment from contamination, long-term stability is crucial. With a multitude of options and varieties of geomembranes available, it can be difficult to make an accurate, direct comparison. For example, when filtering by specification, geomembranes may be similar in physical attributes but have unique performance characteristics.

Wastewater treatment plants often utilize geomembranes to help protect the environment and maximize resources. In San Diego County, the Olivenhain Municipal Water District (OMWD) treats up to 34 million gallons of wastewater each day. The treated water is provided to the community through 45-plus miles of recycled water pipelines. With a seasonal increase in rain, the demand for recycled water drops off and the treated water is stored in a wet weather pond.

You may be wondering why you need to worry about installing a chemical/hydrocarbon-resistant liner to catch spills. After all, if you already have a permanent, above-ground tank or a portable spill unit, the chances of the geomembrane receiving a large spill are very low. Further, the spill may be cleaned up within a short period of time.

.jpg)